Our Vision

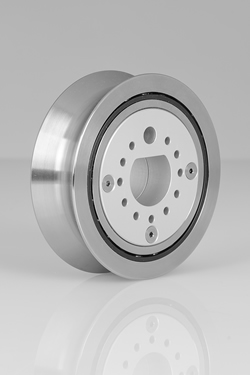

WinMar Racing’s blocks and sheaves combine a unique design (patent pending) with advanced materials, to produce ultra-low friction bearings, even for mis-aligned loads.

Low-friction, even for mis-aligned loads

We understand the reality that blocks and sheaves are often misaligned with the line load, and even a small misalignment can cause conventional bearings to lock-up. Our bearings ensure extremely low friction whether the line load is on-axis or misaligned.

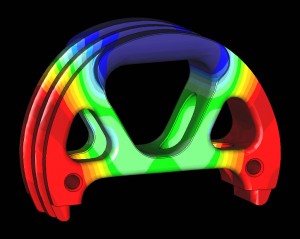

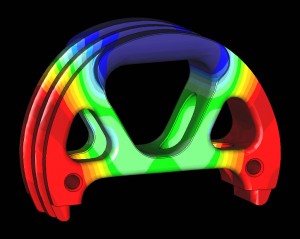

Materials and Production

Our high load blocks and sheaves are constructed of the best grade custom treated titanium, ceramic rolling elements and autoclaved carbon fiber to bring to the market the best product range possible. We have used the latest in finite element analysis software to achieve ultimate performance at minimum weight, packaged in a stylish design. Production is tightly controlled, with each part precisely machined in our CNC manufacturing facility in Italy.

Service and Flexibility

Just as important to us as low-friction and low-weight, the simplicity of our designs provides ease of service to the end-user. Winmar also understands importance of flexibility in its designs and fittings, which is why our blocks and sheaves can be arranged in many different configurations.

Testing

Our product range has been tested extensively in laboratory loading rigs, and in the real world by our rapidly growing list of clients. We currently supply hardware to boats in the following classes:

- America’s Cup AC72

- IMOCA 60

- TP52

- Melges 32

- Volvo 65 (specified)

- A-Class catamaran

- C-Class catamaran

- Ocean racing multihull

- Mini Maxi